Press Brake

Press Brake

WE currently use Amada Press brakes and can communicate notes, programs, punch and die locations across all Brakes. These all come with computers for visual representations of the part we are bending.

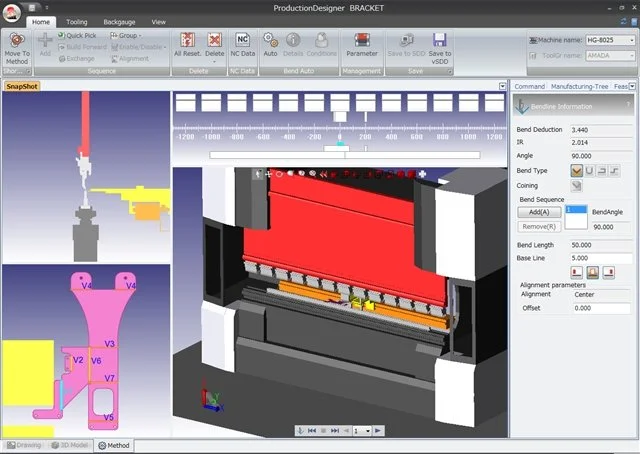

Brake Software

What sets us apart from the others is the use of new technology that allows us to bend a part without starting production.

the use of a 3d Model allows us to bend the part in 3d to provide a visual on the best way to bend the part.

This reduces the amount of scrap, gives us the correct stretch-out, and sends directly to the press brakes when completed so no programming is needed for production.

Capabilities

WE are capable of bending extremely small parts to large parts due to our large capabilities as press brake. With our large Trumf Brake we are able to bend widths of 16ft, depths of 38in, and max tonnages of 400 tons.